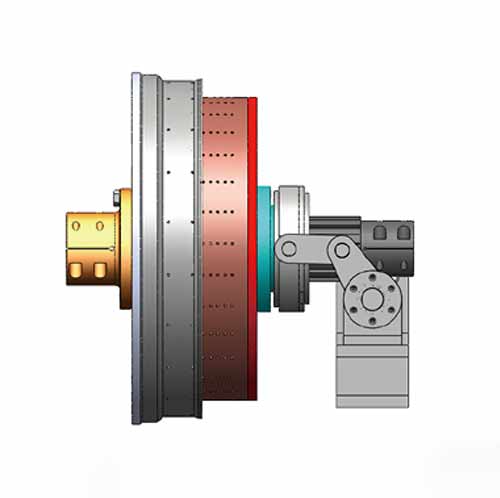

Adjustable Speed Magnetic Shaft Coupling

The adjustable speed magnetic shaft coupling consists of three parts: the permanent magnet rotor, the conductor rotor and the adjustment mechanism. The two rotors are directly exposed to the air for cooling. The permanent magnet rotor and the conductor rotor can be adjusted through the adjustment structure to adjust the axial coupling area. When the main motor drives the conductor rotor Rotating, relative to the permanent magnet installed at the driven end, the circular motion of cutting the magnetic line of force makes the conductor rotor of the driving end generate an eddy current induced magnetic field, which interacts with the permanent magnet magnetic field of the driven end, so as to realize the connection between the driving end and the driven end. contactless torque transmission. The larger the coupling area between the active rotor and the driven rotor, the stronger the magnetic field generated by the cutting magnetic field lines, the greater the torque of the driving load, the greater the speed of the load, and the greater the actual output power. The smaller the coupling area, the weaker the magnetic field generated by the cutting magnetic lines of force, the smaller the torque to drive the load, the lower the speed of the load, and the smaller the actual output power. In actual use, the coupling area is adjusted according to the size of the load, and finally the purpose of speed regulation and energy saving can be achieved.

· It can realize zero-load start, and has overload protection and clutch function,

· Adopt actuator control to adjust the coupling area, which can realize precise control under various loads

· Flexible connection, effectively eliminates system vibration,

· Low centering requirements, easy installation and debugging;

· Adopt self-air cooling structure, basically maintenance-free,

· No pollution to the power grid, no harmonics,

The original system can be easily transformed, and it is more suitable for the connection of the new transmission system

· Long-term stable operation and long service life

· Suitable for small centrifugal equipment fields such as electric power, metallurgy, mining, petrochemical and other fields with a power of less than 630kW.