What is eddy current magnetic coupling?

Eddy current magnetic coupling is a combination of transmission technology, material technology and manufacturing technology. It uses the conductor disk to cut the rotating magnetic field, thereby generating eddy current in the conductor disk, and the eddy current generates an induced magnetic field, which is coupled with the original magnetic field, drives the conductor disk to rotate, and realizes torque transmission.It is widely used with crushers, screens, mills, feeders, belt conveyors and bucket elevators.

Principle

In the initial stage, the distance between the two discs is large, and the motor drives the conductor disc with the copper ring to rotate. After reaching the rated speed, it is close to the magnetic rotor with permanent magnets. Due to the speed difference between the two discs, the conductor disc (eddy current ring) The conductor rotor makes relative motion due to the speed difference. When the conductor rotor copper disc moves, the magnetic induction line is cut, and the eddy current is induced around the direction of the magnetic flux change, and the eddy current generates an induced magnetic field in the copper disc. The induced magnetic field in the copper disc and the permanent magnet. The constant magnetic field interacts to generate coupling torque between the magnetic rotor and the copper disk, so as to achieve the purpose of transmitting motion power. Because the eddy current magnetic coupling works by generating the eddy current induction magnetic field, the generation of eddy current is inevitable. According to Joule’s law, we know that the eddy current will generate heat at every point on the copper disk, and the accumulation of heat on the copper disk will form more heat, and the heat will eventually be dissipated in the form of heat, which causes the eddy current coupling itself dissipates energy. It not only reduces the transmission efficiency and causes energy waste, but also affects the safety performance and reliable operation of the equipment due to the heating of the copper plate.

Calculation of energy consumption

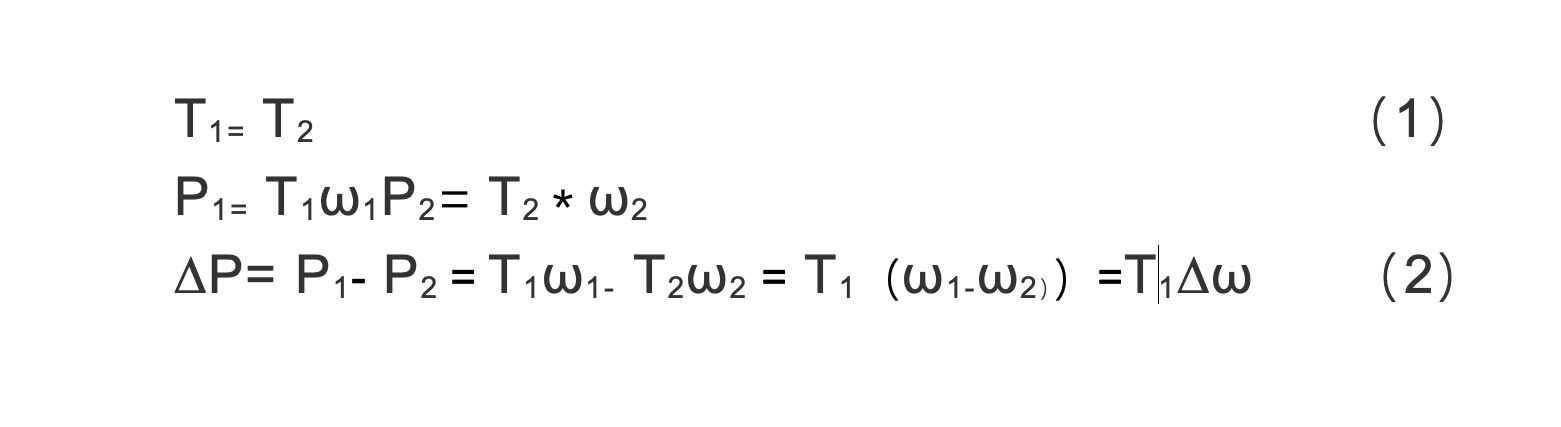

When the eddy current magnetic coupling is working, the greater the speed difference, the more magnetic induction lines are cut, the greater the eddy current and the greater the torque, but at the same time, the more energy consumption is generated. The eddy current magnetic coupling is a constant torque transmission device, that is, the input torque is equal to the output torque, and the power is the product of the torque and the speed difference, so the speed difference produces a power difference, and the power difference is exactly equal to the heat dissipated. Therefore there are the formula:

Among them, T1 is the input torque, T2 is the output torque, Nm. P1, P2 are input and output power respectively, Kw. ∆P is the energy consumption of the Eddy current magnetic coupling, ω2, ω2 are the input and output angular speeds, rad/s.

Energy consumption

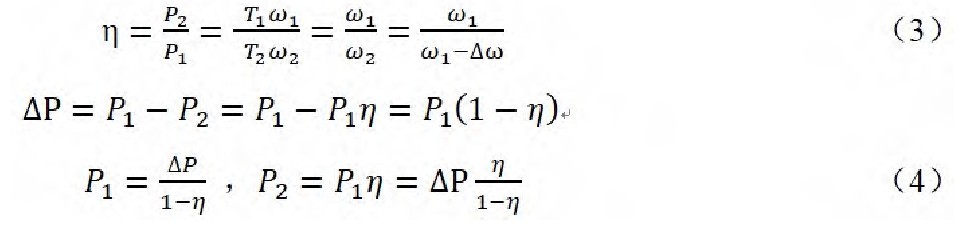

The transmission efficiency of the eddy current magnetic coupling is defined as the ratio of the useful power of the output shaft to the total power of the input shaft, that is

In the formula: η is the transmission efficiency of the Eddy current magnetic coupling, P1 and P2 are the input and output power respectively, and ∆P is the energy consumption of the permanent magnet governor itself.

It can be seen from formula (3) that the transmission efficiency of the eddy current magnetic coupling is only related to the speed difference between the driving disc and the driven disc, the smaller the speed difference, the higher the efficiency. It can be seen from formula (4) that the power consumption of the eddy current magnetic coupling is proportional to the transfer power consumption, the transfer power consumption is large, and the energy consumption is also large, so the heat generation of the high-power governor is very serious, and its thermal design is very necessary .

Simulation research analysis

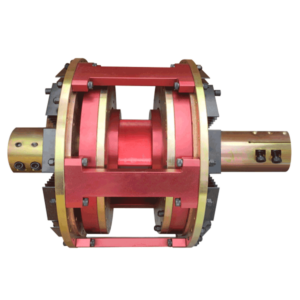

In the application of construction machinery and equipment, the most important thing to pay attention to is the efficiency of the equipment. In this post it is an idealized model in actual engineering. After determining the input power and speed difference, the torque value is obtained through Ansoft maxwell simulation. Figure 3 is a model diagram of the disc eddy current magnetic coupling established by software:

Two kinds of eddy current magnetic couplings with different structural parameters were simulated , and the number of magnetic poles was 16 pairs. Here are the dimensions:

Outer radius of yoke plate:150mm

Outer radius of copper plate:142mm

Inner radius of copper plate:70mm

Outer Radius of Magnet:140mm

Inner Radius of Magnet:75mm

Tab.1 The size of eddy current magnetic coupling

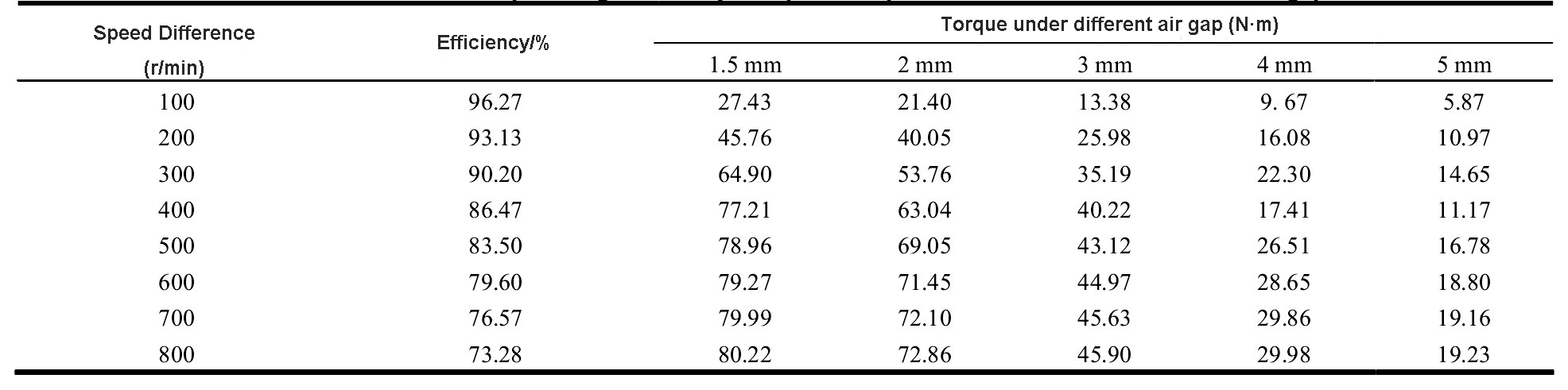

Tab.2 The relationship among efficiency, torque and speed difference under different air gap

It can be seen from Table 2 that under the same speed difference, the efficiency is the same at different air gaps. It can be concluded that the air gap thickness of the Eddy current magnetic coupling has no effect on the transmission efficiency, and the transmission efficiency is only It has a great relationship with the speed difference.

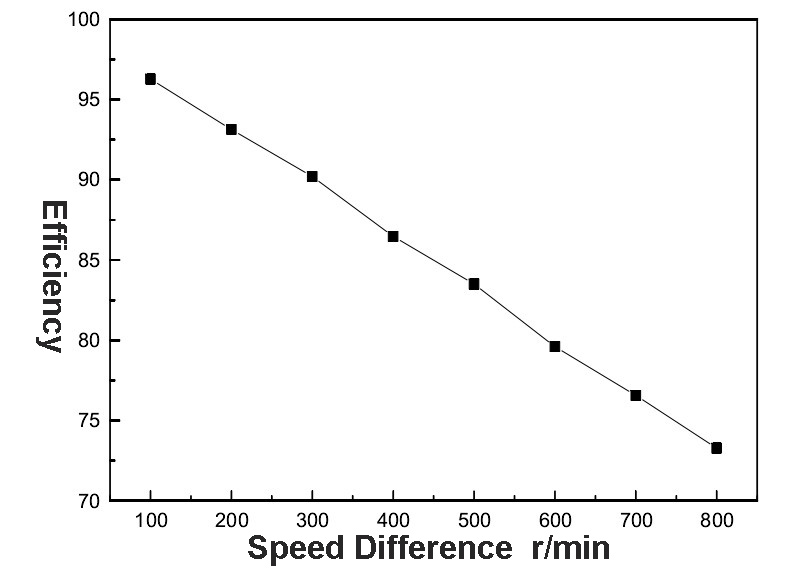

Figure 4 is a graph showing the relationship between the speed difference and efficiency of the eddy current magnetic coupling, from which it can be concluded that as the speed difference increases, the transmission efficiency decreases linearly.

This is because when the eddy current magnetic coupling works, the greater the speed difference, the more magnetic induction lines are cut, the stronger the eddy current is generated, and the greater the torque is, but at the same time, the higher the energy consumption is, the lower the efficiency is. .

Conclusion

In this post,we analyzes the working characteristics and energy consumption characteristics of the eddy current magnetic coupling. As an energy-saving device, the eddy current magnetic coupling itself also consumes energy.

The cause of energy consumption is analyzed and the energy loss is calculated. Starting from the energy point of view, the law of energy consumption is explored, that is, the relationship between energy consumption and input power is proportional. Using Ansoft maxwell finite element simulation software to simulate and study the eddy current magnetic coupling, it is found that the energy consumption of the eddy current magnetic coupling has nothing to do with the thickness of the air gap, and is only determined by the structure of the Eddy current magnetic coupling; The transmission efficiency of the eddy current magnetic coupling has nothing to do with the thickness of the air gap, and it decreases linearly with the increase of the speed difference.