Torque limited magnetic coupler in Crusher

Table of Contents

The double-geared roller crusher has the advantages of light weight, small size and low energy consumption, and is suitable for various operating environments, and has been widely used in coal mines. In the open pit coal mine, the large volume of raw coal is crushed by the double-geared roller crusher and then transferred to the coal bunker or the secondary crusher through the belt conveyor. Since the raw coal is often mixed with hard materials such as gangue and iron blocks, the double-geared roller crusher often stops under load, causing equipment damage. At present, coal mine production enterprises often use torque-limiting hydraulic couplers as overload protection devices to maintain the normal operation of double-geared roller crushers. However, in open-pit coal mines, the crusher is loaded with strong impact, and the vibration is large, and the hydraulic coupler often leaks oil, which affects the normal use of the equipment. At the same time, when the ambient temperature is low in winter, the hydraulic coupler is easy to melt and plug. When the crusher is blocked and shut down, it cannot effectively protect the equipment, which may cause production accidents.

Different from the hydraulic coupler, the torque limited magnetic coupler uses the magnetic field as the medium, and relies on the interaction between the magnetic fields to realize the effective transmission of torque. Compared with the hydraulic coupling, it has the advantages of high efficiency, fast dynamic response, convenient maintenance, etc., and has been widely used in the field of coal mines.

Torque limited magnetic coupler

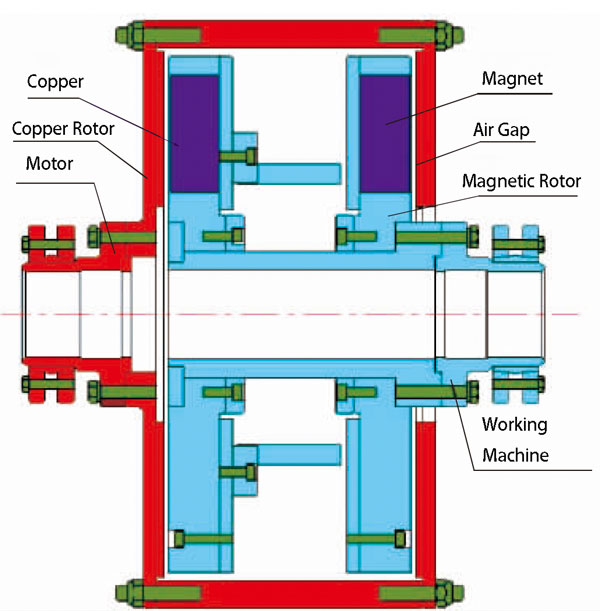

The magnetic coupler is mainly composed of an input component and an output component, and a permanent magnet is installed on the output component to provide the main magnetic flux of the air gap. When the input component and the output component are relatively displaced, the copper ring cuts the main magnetic flux of the air gap to generate eddy current, and the interaction between the eddy current magnetic field and the main magnetic field of the air gap generates torque and realizes the transfer of energy from the motor to the load. Since there is no physical contact between the input and output components of the magnetic coupler, it has the advantages of low centering requirements and vibration isolation. Under normal circumstances, the slip ratio of the magnetic coupler is 0.01 to 0.03 during rated operation.

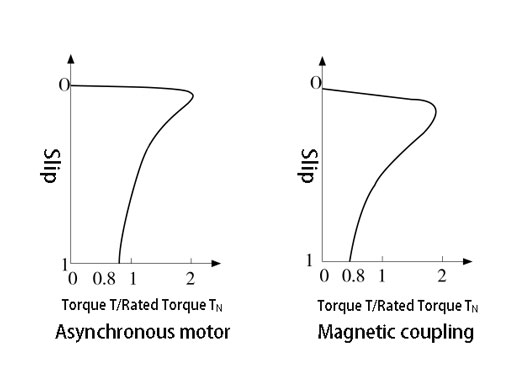

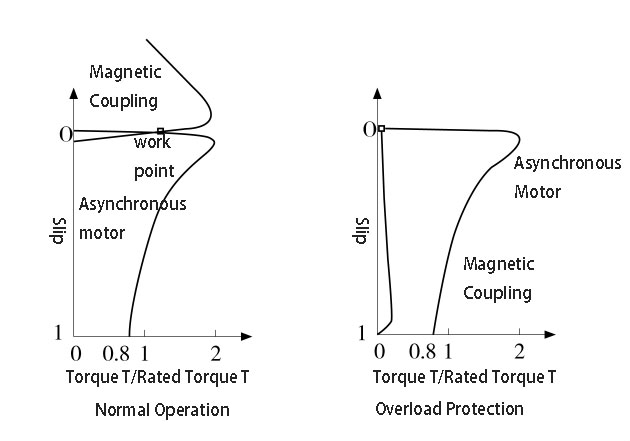

The operation curve of the magnetic coupler and the motor is shown in Figure 2. Since the input speed of the magnetic coupler is the output speed of the motor, when the magnetic coupler and the motor work together, the curve of the magnetic coupler flips up and down, and the intersection between the two curves is the operating point of the motor and the magnetic coupler. Different operating conditions of the torque-limiting magnetic coupler are shown in Figure 3.

The slip speed of the magnetic coupler increases with the increase of the load. When the load torque is greater than the limit value, the axial force of the magnetic coupler becomes larger, the output component is separated from the input component, and the motor runs without load, realizing the function of overload protection of the motor. .

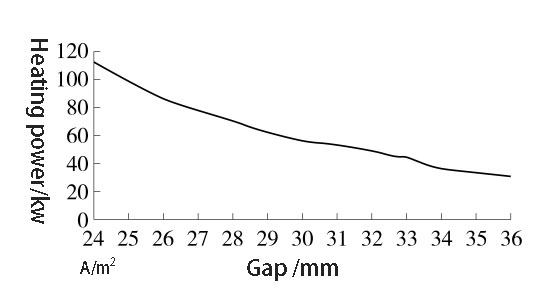

Reconstruction of the Torque limited magnetic coupler

At present, the rated power of the on-site crusher motor is 220 kW, the rated current is 25.1 A, the motor current is 8.5 A during no-load operation, and the normal operating current is about 14 A. Due to the on-site working conditions, the crusher motor often experiences shock changes, and the strong shock load can instantly reach 4 to 5 times the rated power of the motor, which is more than 10 times the normal operating power. When the torque-limiting magnetic coupler is overloaded, the motor is equivalent to no-load operation, and the motor current is not much different from the no-load operation of the crusher. An overload protection detection system needs to be built. When overload protection occurs, the on-site staff can be reminded to deal with it. Usually the operation status of the magnetic coupler is monitored by the sensor, but since the primary crusher of the open pit mine is installed outdoors, the ambient temperature in winter can reach as low as -50 ℃, and the electronic control equipment and sensors cannot work normally in such a low temperature environment Therefore, it is necessary to build an electronic control system that can accurately judge whether the torque-limiting magnetic coupler is overloaded. Due to the on-site collection of motor running current, combined with the working conditions of constant current during no-load operation of the motor and shock changes of current during on-load operation, the heating power of the torque-limiting magnetic coupler during overload protection operation is set to be slightly higher than 70 kW. , so that the current of the motor is stable at about 12 A when the load is locked and stopped, which is convenient for the electric control system to judge.

Torque limited magnetic coupler

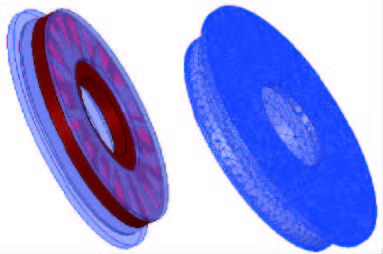

Since the overload factor of the torque-limiting magnetic coupler is generally around 2.0, in order to meet the needs of strong impact loads, it is necessary to increase the rated power of the torque-limiting magnetic coupler. 1: 1.05: 1.1 is changed to 2: 1.05: 1.1, so that the torque-limiting magnetic coupler can still have overload operation ability under strong impact, so as to avoid affecting the normal operation of the crusher. The three-dimensional finite element model of the magnetic coupler is shown in Figure 4.

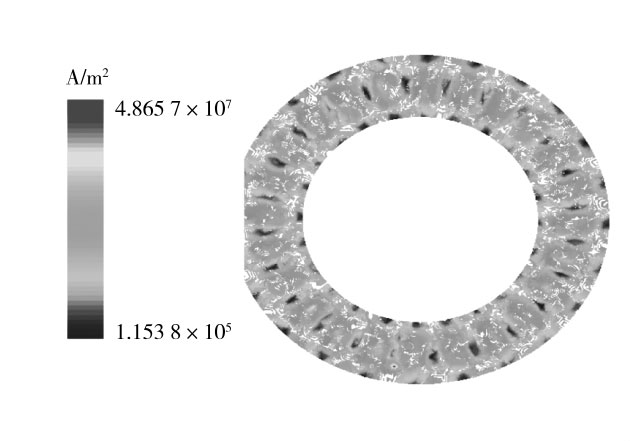

The motor power of the primary crusher on site is 220 kW. According to the matching principle and existing product models, the rated power of the torque-limiting magnetic coupler is selected to be 400 kW. The three-dimensional finite element analysis software is used to model and simulate the magnetic coupler, and the eddy current distribution of the copper plate during the rated operation of the magnetic coupler is shown in Figure 5. The operating point change when the maximum air gap is changed is shown in Figure 6.

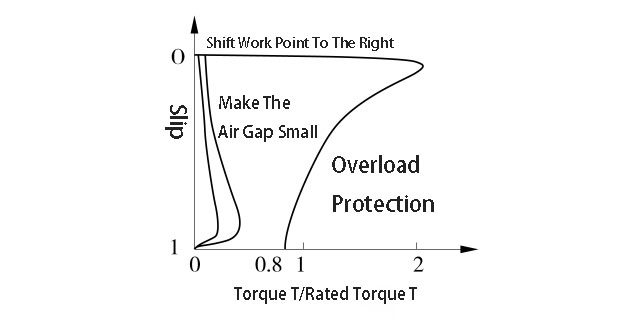

Due to the overload protection of the coupler when the crusher is locked, the motor is running at no load at this time, and the electronic control device cannot accurately distinguish the current state and the no-load operation of the crusher. The air gap is designed [10]. The torque-limiting magnetic coupling overload protection transmission torque is shown in Figure 7. It can be seen from Figure 7 that reducing the maximum air gap of the magnetic coupler can increase the heating loss of the coupler during overload protection. The reasonable design of the maximum air gap can make the crusher’s stall current and no-load. The current is effectively distinguished, and the overload protection alarm function is realized.

Compared with Fig. 7 and the no-load condition of the on-site motor, it is reasonable to design the maximum air gap of the magnetic coupler as 28 mm. When the magnetic coupler is running at the maximum air gap, the transmission torque of the coupler is about 450 N°§m. At this time, the input current of the motor is stable between the no-load current and the load current, which is convenient for the electronic control device to judge the magnetic coupling. the operating status of the device.

Transformation

The structural characteristics after the transformation.

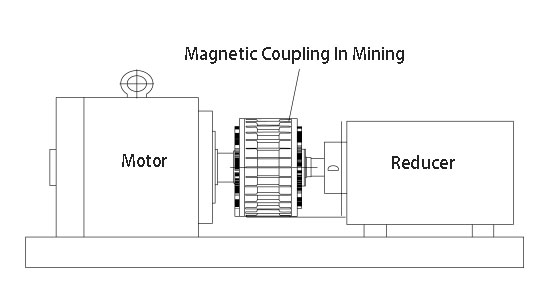

The original double-geared roller crusher uses a torque-limiting hydraulic coupler as the transmission equipment. The interface size of the magnetic coupler used for the transformation is the same as that of the hydraulic coupler, and the drive system only needs to change the axial installation space. After the transformation, the axial installation size is increased from the original 460 mm to 500 mm, and the motor is moved backward by 40 mm. This modification requires a small amount of engineering and low investment cost. Since the torque-limiting magnetic coupler has low requirements for axial alignment, the transformation process is fast, and the installation diagram after transformation

Features of operation and maintenance after renovation

Due to the large impact of the load, the original hydraulic coupler often leaks oil due to vibration, and the vibration will cause damage to the motor and reducer bearings, requiring workers to regularly check and maintain. The modified double-geared roller crusher uses a torque-limiting magnetic coupler as the transmission equipment. There is no filler inside the coupler, and the characteristics of vibration isolation make the entire drive system run smoothly, basically maintenance-free and save a lot of manpower and material resources.

The overload protection performance after transformation

The torque-limiting hydraulic coupler needs to melt the fusible plug to realize the overload protection function. The response time is full, and it is easy to fail to operate in winter. On the other hand, the overload protection of the hydraulic coupling will affect the surrounding environment when injecting fuel, and it needs to be manually injected before it can run again. After using the torque-limiting magnetic coupler, the overload protection is correspondingly fast, and there is no requirement for the surrounding environment.

Conclusion

After the transformation of the double-geared roller crusher with a torque-limiting magnetic coupler, the crusher runs reliably, the motor vibration is significantly reduced, the failure rate is reduced, the normal operation time of the crusher is improved, and the overload protection performance is effectively improved. The alarm function operates reliably, reduces the labor intensity and maintenance cost of maintenance personnel, and saves manpower and material resources.