Table of Contents

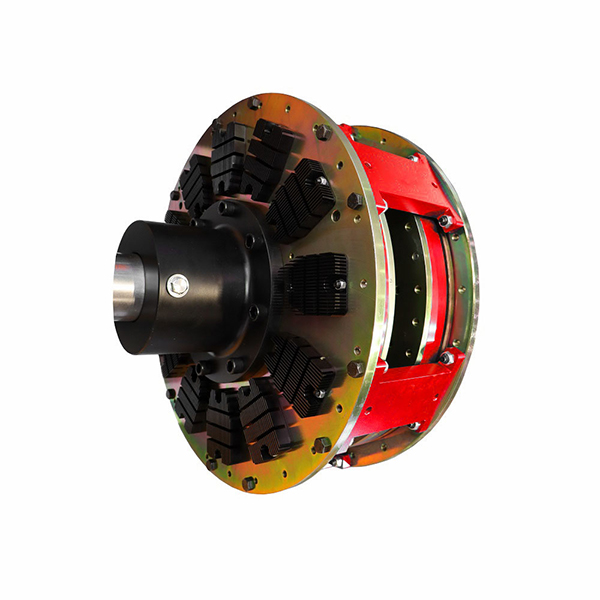

Torque limited magnetic copouled

The Torque limited magnetic coupled has the characteristics of high efficiency, energy saving, environmental protection, and safety. At the same time, it can replace hydraulic coupling, flexible coupling, and other products to realize functions such as soft start, torque limit, and speed regulation, and provide a guarantee for the efficient and worry-free operation of equipment.

Background

An iron ore processing plant is equipped with 4 sets of CH870 cone crushers, equipped with 600kW six-pole motors, and the motors and crushers are connected by tire coupling. The tire coupling relies on the friction force generated between the tire and the flange end face to transmit torque by tightening the bolts, and the torsional shear deformation occurs when the tire ring is working. The crusher was disconnected due to the huge shearing force due to the jamming of the crusher.

The necessity of project renovation

Crusher is a very important equipment in the crushing process of iron ore industry. The original drive system is generally in the form of “asynchronous motor + torque limited hydraulic coupling/other flexible coupling”. Transforming into a magnetic coupled can realize soft start and torque limit protection functions, protect the host equipment, motors, shafts and bearings, reduce the amount of on-site maintenance equipment maintenance, no oil, no electricity, no consumables and spare parts, and comprehensive benefits. improve. The production of iron ore processing plant is a continuous process. The shutdown of the entire production line due to equipment failure is very serious for the enterprise, so it is of great significance for the production line to improve the stability of key equipment.

About the torque-limited magnetic coupled

How does torque-limited magnetic coupled works

The torque limited magnetic coupling is a device that uses the principle of magnetic induction to work. It consists of two independent parts without rigid connection, and transmits torque through the interaction between the magnetic fields. A conductor disc assembly fitted with a copper ring is connected to the motor shaft. A magnet disc assembly equipped with strong rare earth permanent magnets is attached to the load shaft. The relative motion between the conductor disk assembly and the magnet disk assembly generates eddy currents in the conductor disk, and generates a strong magnetic force between them, thereby realizing the function of transmitting torque in the air gap. When starting the motor operation, the magnetic coupled will automatically change the size of the air gap to achieve the output torque required by the load. When the load is jammed or overloaded, the speed of the load shaft drops rapidly. At this time, the coupling will automatically increase the air gap to the torque release state, reduce the torque transmission, and even cut off the load output, thereby protecting the motor and the load equipment. After the overload or related faults are removed, restart the motor, and the coupling will automatically re-enter the normal working state.

Feature of torque limited magnetic coupled

The torque limited magnetic coupled has structural and functional characteristics that cannot be compared with the hydraulic coupling, mainly as follows:

Structure:

The torque limited magnetic coupled is not only simple in structure, but also has no independent moving parts, so there are no problems such as wear, vulnerability and seal leakage, which greatly improves its reliability and service life. , and reduce maintenance costs.

Installation and centering:

The conductor disk and the permanent disk are respectively fixed on the motor and the load shaft, and there is no mechanical constraint between the two except for the interaction of the axial magnetic field force. Therefore, there is no strict limit on shaft alignment and shaft inclination error during installation. Generally, the inclination angle of the shaft is not more than 1.5°, which can ensure normal operation, and the installation difficulty has been greatly reduced.

In terms of noise and vibration:

After installing the torque limited magnetic coupled, the noise and vibration are greatly reduced. More than 80% of rotating equipment will fail due to vibration, most of which is due to shaft misalignment, in addition to equipment imbalance and resonance. The torque-limited magnetic coupled is not in physical contact and transmits torque through the air gap. Experiments show that the use of the torque-limited magnetic coupled can isolate up to 80% of the vibration transmission.

Soft start function:

soft start, the starting current is obviously reduced. After using the torque limited magnetic coupling, the motor accelerates to the maximum speed during startup, and under the influence of the coupled magnetic field, the load starts smoothly and finally accelerates to close to the motor speed. Under normal circumstances, the starting peak current when the system uses the torque limited magnetic coupled is only about half of the starting peak current when the torque limited hydraulic coupling is connected. In the operation of crushers, zippers, belt conveyors and other equipment, the impact of the impact load during startup and operation is greatly reduced, and the service life of the equipment is prolonged.

In terms of heat dissipation performance:

the torque limited magnetic coupled also relies on the speed difference to achieve torque transmission. The greater the slip, the greater the coupling torque, but the greater the eddy current heat loss; It is converted into the heat of temperature rise on the conductor and absorbed by the air. Under the same slip, the eddy current loss heat decreases exponentially with the increase of the air gap.

Overload protection performance:

The torque limited magnetic coupled has the functions of locked rotor and overload protection. When the equipment is working normally, when the torque of the load end suddenly increases and exceeds the safe torque of the transmission device (about 1.8 times the rated torque of the motor), the speed of the load shaft drops rapidly, and the coupling will automatically increase the air gap to A “torque disengaged” state, which reduces torque transfer. The torque delivered in the “torque disengaged” state is approximately 5% of the rated torque of the motor. The transmission will maintain this state until the load end decreases below the safe torque, that is, when the fault is removed, the load end speed gradually increases, and the torque limited magnetic coupled enters the normal working state again. It can be seen that the overload protection process of the torque limited magnetic coupling can be completed automatically and is reversible without manual participation, which is safe and efficient.

Environmental protection requirements:

torque-limited magnetic coupling junction

Simple structure, basically maintenance-free, no need for lubrication, so there is no pollution damage to the environment. To sum up, the torque limited magnetic coupling not only has all the functions of the torque limited hydraulic coupling, but also has its unique technical characteristics. Compared with the torque limited hydraulic coupling, the torque limited magnetic coupling has obvious technical advantages, and can solve the problem that the hydraulic coupling has been eagerly looking forward to solve in the production practice for a long time but has not been solved. Therefore, in the iron ore processing industry, it is a very ideal choice to use the “torque limited magnetic coupling” to replace the original “torque limited hydraulic coupling”.

Comparison of Torque Limited Magnetic coupling and Tire Coupling (Table 1)

| Table 1 | ||

| Feature | Tir Coupling | Torque limited Magnetic coupling |

| Soft start effect | Better | Best |

| Stall protection | fracture | Slip protection + lock-rotor automatic release double protection |

| Vibration isolation | Vibration is reduced by about 70% | Vibration reduced by up to 80% |

| Alignment requirements | The axis of the rotation is not coincident, and it is easy to vibrate | very low |

| Ambient temperature requirements | 20℃~80℃ high temperature, accelerated aging | 40℃~100℃ can be used |

| maintenance requirements | Frequent replacement of spare parts when the rotor is blocked | Maintenance-free, no consumables |

| transfer efficiency | About 98% | More than 97% |

| cost of investment | More expensive, spare parts occupy more funds | High one-time investment cost |

| service life | The number of jams is determined | ≥20 years |

Retrofit plan

Technical parameters of cone 600 kW crusher equipment

| Table 2 | |

| Equipment | Cone Crusher |

| Motor | 600kW, 990rpm |

| Quantity | 1 pcs |

| Motor shaft | Φ120*208mm |

| cone crusher shaft | Φ140*140mm |

| Axial length | 610mm |

Technical parameters of torque limited magnetic coupling (Table 3)

| Table 3 | |

| Product | HCOX series torque limited magnetic coupling |

| Model | HCOX-X1000 |

| Brand | HCOX |

| Product type | Moment limited |

| Permanent magnet rotor parts | Sintered NdFeB, Aluminum, Steel |

| Conductor rotor parts | Steel, copper |

| Input speed | 1500rpm |

| Maximum output speed | 1500rpm (97-99% of motor rated speed) |

| Work efficiency | More than 97% |

| Angle tolerance | 1.5° |

| Maximum transmission torque | 6077N m |

| Stall protection torque/motor rated torque | 1.8 times |

| Minimum working ambient temperature | -40℃ |

| Maximum working ambient temperature | +100℃ |

| Structure type | Disc type (AB-BA symmetry) |

| Hub type | Split hub (with flat key) |

Modification

Remove the “original tire coupling” and replace it with a “torque limited magnetic coupling”. The original drive part, including the motor, tire coupling, and the crusher body has an independent mounting base. After the transformation, the torque limited type is used. The magnetic coupling adapts to the characteristics of wide shaft spacing, keeps the original layout size of the entire drive unit unchanged, is easy to retrofit and install, and has a small debugging workload.

Project Benefit Analysis

According to the statistics of spare parts consumption in the past two years, the CH870 cone crusher consumes 2.5 sets of flexible connection units per year, and the cost is about 18,000 USD. The cost of transforming the magnetic coupling is 40,000 USD per unit, the service life of the equipment is 15 years, and the equipment investment payback period is 2.25 years. At the same time, the replacement of the magnetic coupling can greatly reduce the downtime of failure, and ensure the safe and stable operation of the cone crusher.